Power flushing service

We are experts in power flushing old systems. All systems need power-flushing before a new boiler is fitted, and need power-flushing to maintain the good regulation of the system. Power-flushing will soon be a regulation to be followed for all official installers.

This is the process by which heating systems are forcibly cleansed using water at high velocity, but low pressure, so that no physical damage is caused to the system. The process is made even more effective with the addition of powerful cleansing and mobilising agents.

The objective is to restore systems with circulation and boiler noise problems (caused by sludge and corrosive deposits) to optimum operation. Power flushing removes these deposits and the problems that they cause.

Fuel wastage

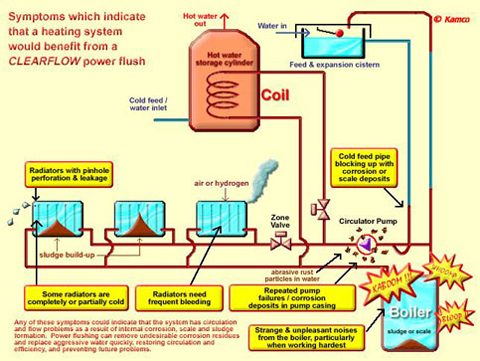

Cause: In untreated heating systems, corrosion debris accumulates in the boiler and, in hard water areas, lime scale will form. The insulating effect of these deposits reduces heat transfer to the circulating water. 3mm of lime scale deposit on the heat exchanger will add 18% to your fuel bill. It is in the current British Standards requirements that prior to boiler change, the system must be cleaned, power-flushing is the best way to achieve a proper job.

Boiler failure

Cause: Assuming no other faults exist, the insulating effect of accumulated deposits of sludge and scale can restrict the transfer of heat to such an extent that the boiler overheats and fractures.

Pump seizure and failure

Cause: Black oxide sludge, being abrasive and magnetisable, increases shaft and bearing wear which is the most common cause of sticking pumps and pump failures.

Cold radiators

Cause: Sediment of iron oxide sludge accumulating at the bottom of radiators restricts the flow pattern.

Frequent venting, cold spots near the top of the radiator

Cause: Sediment of iron oxide sludge accumulating at the bottom of radiators restricts the flow pattern.

Sludge and scale

Cause: Black Oxide sludge forms continuously in all unprotected central heating systems as a result of corrosion. It will also harden into scale on the hottest surfaces of a system. (i.e. the boiler heat exchanger causing it to make knocking and kettling noises). This prohibits efficient heat transfer.

Boiler manufactures will not guarantee your new boiler installation if the system is not chemically cleaned. The British Standards and the Benchmark demand that the system should be thoroughly cleaned. It is prudent to power flush a heating system immediately before fitting a new boiler to an existing system to prevent possible future problems.

Many systems are found to contain corrosion and sludge, even if no flow problems have yet shown themselves. Existing debris is often mobilised by alterations to the system / piping and the increased efficiency of the new boiler, and may then accumulate in the boiler heat exchanger, causing noisy operation, reduced efficiency and, in extreme circumstances, failure of the boiler.

The high efficiency and compactness of modern boilers, developed to minimise fuel costs and pollution, means that they are more susceptible to problems caused by debris in the system water.

How does it work?

The CLEARFLOW power flushing pump is simply connected into the heating system, either across standard circulator pump couplings, across the tails of one radiator, or wherever most practicable. The powerful flow, combined with instantaneous flow reverser device, will dislodge and mobilise deposits and corrosion which resist traditional system cleaning methods.

Once the corrosion and sludge deposits have been loosened and mobilised, fresh clean water is forced through the heating system, pushing the contaminated water out through a full bore dump valve to waste. During the CLEARFLOW process, radiators are individually flushed, without removing or disconnecting them from the system, by directing the full output of the pump through each radiator separately.

At the end of the flushing process, the system contains fresh clean water and reinstatement of the system to normal operation takes only a few minutes. System flushing will not remedy design or mechanical faults, which should be rectified but, in many cases, it will cure the problems caused by these.

Can I use a descaling pump for power flushing?

Most smaller descaling pumps are not powerful enough to effectively flush a central heating system. They don’t have the vital flow rate or the pressure needed to maintain flow against the resistance of the heating system.

What is the difference between a descaling pump and a power flushing pump?

Power flushing pumps have not only been constructed to purge the system with fresh water whilst dumping the contaminated water, but are also supplied with flow and return hoses, dump and water inlet hoses, valves to isolate them from the system, adapters to speed connection into a system and a significantly higher performance rating.

Payment options

- Visa

- Visa Debit

- Visa Electron

- Mastercard

- Discover

- Diners Club

- Maestro

- JCB

Areas covered

- Alresford

- Fareham

- Hambledon

- Lyndhurst

- Romsey

- Southampton

- Stockbridge

- Winchester